GAP Certification FAQs

Click the question to go to the answer on this page.

- Does my farm need to be GAP certified?

- What is the process for becoming GAP Certified?

- How much does a GAP Audit cost?

- If my produce is GAP certified, does that mean I will make a higher premium for it?

- Does being GAP certified mean my produce is safer?

- If I am growing a large number of vegetables and/or fruits, must I be GAP certified for all of these crops?

- What if I have a mixed operation with livestock—can I still get GAP certified?

- If I am using my own prepared compost or purchasing compost as a soil amendment, what are some important to considerations?

- What constitutes flooding of production fields, and what measures would need to be taken if flooding did occur?

- Do I need to fence out wildlife to comply with GAP, or are there other acceptable methods?

- If I choose to be audited on the ‘Field Harvest and Field Pack’ section of the USDA GAP audit, does the auditor need to see me harvest each specific crop?

- When harvesting, should I have a way to label product moving from the field to packing area (if re-packed)?

- Can pathogens be removed by washing produce?

- What recommendations can you give for sanitizing tools, bins, and packing areas?

- What are some considerations for GAPs for tree fruit production?

- Can a farm using an aquaponics system be GAP-certified?

- What if my buyer requires GAP certification before they will purchase my product? How can I still perform a mock recall?

- When should I begin preparing for my GAP audit?

Does my farm need to be GAP certified?

This is a common question we are always asked. To find the answer, you need to consult with your buyers and also weigh the costs/benefits. While with some larger retailers or wholesalers having a food safety audit is an absolute necessity in order to sell product to them, other buyers--like restaurants, public schools, and direct sales venues like roadside stands and farmers markets--typically do not require a food safety audit. Communication with your potential buyers is crucial to know what their expectations and requirements are. Additionally, they may require very specific audit schemes such as the USDA Harmonized GAP, Global GAP, or other food safety audit. Always talk with your prospective buyers first and ask them what they need in the way of food safety training, documentation, audits, and liability insurance. This will save you a lot of time, energy, and money. Additionally, given the expenses associated with an audit, it is wise to weigh all of the associated costs for obtaining an audit, and determine if the market access you will be gaining is financially beneficial. In other words, if getting into a particular market has many hurdles without significant returns, it might make more sense to look at other market options.

What is the process for becoming GAP Certified?

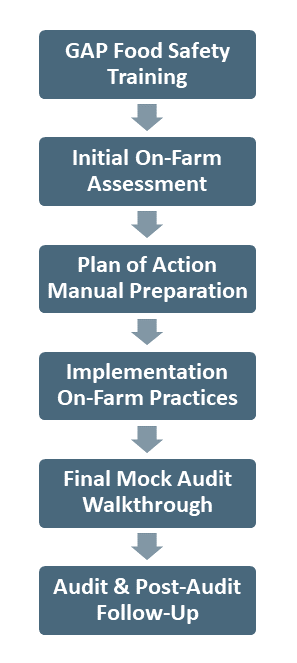

Once you have determined you need to be GAP certified, we recommend you contact the Fresh Produce Food Safety Team to discuss next steps (see figure below). Typically, we recommend attending an initial training in which we discuss associated on-farm contamination risks and practices that mitigate those risks. We then like to conduct an on-farm assessment by coming to your farm to walkthrough, see your process from planting through harvest and post-harvest handling.This helps to guide the next steps of the process, which include the development of your POA manual (which we have templates and good starting points for), as well as implementing on-farm compliance components. Once these steps are completed, we suggest a final mock audit walkthrough to make sure everything is in place before scheduling the audit inspection. Then, we encourage you to schedule a date with VDACS for the actual audit, in which they will review your POA manual and walk around the farm to make sure that all the steps have been taken to be compliant as specified in the manual. When possible, we suggest the local agent who has assisted you be present for the audit so they can take notes of any areas needing attention. Once the audit is complete, you can discuss these areas and make adjustments. For more information, see http://www.pubs.ext.vt.edu/HORT/HORT-252/HORT-252.html.

How much does a GAP Audit cost?

Costs of audits vary depending on what audit you get. The USDA GAP and Harmonized GAP audits are cheaper than other audits like Global GAP or GFSI audits. In Virginia, VDACS acts as the third party on behalf of USDA, and their charge for travel time, audit time, and in office processing is $108 per hour. In addition, there are associated costs with readying your farm to be GAP-compliant, such as water testing, water treatment (if necessary), signage, developing worker wash stations, eating areas, traceability codes (stamps or labels), etc.. There is also the time for the preparation of the manual (Plan of Action or POA) including all the required documentation you need to pull together. The price just for the inspection costs is likely between $550-750, as the audit usually takes around 2 ½ -3 hours depending on how spread out your farm might be or if there are multiple field sites to inspect, and the time needed by the inspector to travel to and from your farm, and any in-office time. The Harmonized GAP (HGAP) audit is more extensive in terms of the checklist of questions and documentation, so is costlier to obtain.

If my produce is GAP certified, does that mean I will make a higher premium for it?

Unfortunately, GAP certified product does not guarantee a higher pay-off. This is especially true at the wholesale level vs direct market level. Having said that, one thing that GAP certification may do is open new markets that were otherwise closed since more and more buyers want some sort of assurance (as much as is possible) that a grower is doing their best to provide a quality and safer product. Being GAP certified is one way growers can show buyers that they are making concerted efforts to take food safety seriously. It is also important to recognize that more and more buyers are requiring some sort of food safety plan and documentation or verification of practices. While a grower can never totally eliminate risks, growers knowing their risks, implementing best practices, and having documentation often increases the quality and uniformity of their product and is definitely a plus in the marketplace.

Does being GAP certified mean my produce is safer?

While we might assume that someone with a passed GAP audit has a safer product, this just is not true. In fact, some of the worst fresh produce foodborne illness outbreaks were linked back to farms that had successfully passed their food safety audits. Audits are a single snapshot in time. Commitment to food safety needs to be a deeply rooted value that drives a farm’s philosophy and approach. So, regardless of what market you are selling to or whether or not you become GAP certified, what is more imperative is to understand the potential contamination hazards and ways that contamination can occur on farm during production, harvest, and post-harvest handling stages. Once you have assessed your farm in this way, you can then incorporate GAPs to reduce and mitigate risks.

If I am growing a large number of vegetables and/or fruits, must I be GAP certified for all of these crops?

It is important to remember that for any given farm getting certified, you specify which crops you want to be certified. While some farms do get all of their produce GAP certified (i.e. ‘mixed vegetables’), some farms opt to focus on a particular crop instead. This provides flexibility for a farm and also allows a farm that may be incrementally scaling up their food safety efforts, to do so at a more measured pace (i.e. to focus on particular crops at first and gradually include more crops in future audits). A key with this approach is to make sure that there is some sort of physical segregation of product, and to also make sure that GAP produce is not co-mingled with non-GAP produce. It is also important to make sure that there is a thorough understanding of food safety risks, routes of contamination, and best practices.

What if I have a mixed operation with livestock—can I still get GAP certified?

Yes! There are many farms that are GAP certified that also have integrated livestock along with fresh produce. The key is to make sure that all the food safety risks are understood, that any cross contamination concerns are addressed, and that best practices are put into place. Consider all production practices, harvesting, and postharvest handling, and look at each and every step of your processes, so you can identify where the hazards are and put practices into place that will address and minimize those hazards. Because cross contamination is such a potential problem in mixed operations, it is important to make sure workers, boots, clothing, tools, equipment, tractors, etc.., do not become a means for fecal contamination.

If I am using my own prepared compost or purchasing compost as a soil amendment, what are some important to considerations?

From a food safety standpoint, a primary concern is whether or not raw manure or any animal products are being used to make the compost. In addition to the materials used, is the process by which the compost was made, and whether or not it was a passive or active process. Active and passive compost processes are very different, and it is important to understand how these two processes impact the finished product. For GAP certification, an active process is required if any manures were used for making the compost. An active process means the pile is turned and monitored in order to achieve adequate maximum temperatures, and maintain moisture and oxygen levels over a minimum timeframe. These conditions are critical to kill human pathogens that might be present in the raw manure. Some questions to ask are:

- What ingredients or materials (often referred to as composting feedstocks) went into making the compost? Obviously manures are going to pose more risk than other feedstocks.

- What process was used to make the compost? Was the pile simply stockpiled, or was it actively turned, and temperatures monitored and maintained for enough time to reach temperatures needed to destroy human pathogens? Are there records that you kept to document the process used and to measure time, temperature, etc.?

- There are independent laboratories that can provide testing. One test that can be used is called the Solvita test, https://solvita.com/ , which is a test kit, although it is pricy. The compost can also be sent to Woods End Laboratories for testing at https://woodsend.org/, which provides various analyses for compost. You would need to ask about the cost of any analysis.

- If the compost was purchased, do you have documentation from the composter? Reputable commercial composters should be able to provide a label, along with a certificate of analysis. This information should detail what feedstocks went into their compost and provide details on the process they used, temperatures maintained, how long, etc..

- All of these various analyses or records are important in order to provide documentation for the audit.

What constitutes flooding of production fields, and what measures would need to be taken if flooding did occur?

“Flooding is the flowing or overflowing of a field with water outside a grower’s control. Pooled water (e.g., after rainfall) that is not reasonably likely to cause contamination of the edible portions of fresh produce is not considered flooding”. The main concern with flooding is the potential for contamination by fecal matter, such as sewage, and any other contaminants like chemicals, heavy metals, pathogenic microorganisms or other contaminants. If there is reason to believe the edible portion of the crop was exposed to flood waters, then this produce is considered adulterated, and cannot enter into human food channels. If the edible portion of the crop was not exposed to flood waters, then it is important to assess whether or not the crop is still safe for human consumption. For more guidance, see https://www.fda.gov/food/guidanceregulation/guidancedocumentsregulatoryinformation/emergencyresponse/ucm287808.htm

Do I need to fence out wildlife to comply with GAP, or are there other acceptable methods?

While fencing out wildlife is highly desirable, the reality is that the cost to do so is often prohibitive, especially for farms that have a lot of acreage. Main goals for controlling wildlife are: observe and monitor for the presence of wildlife (looking for feces, tracks, damaged crop, etc.); use deterrence (canons, screechers, scarecrows, traps) and exclusion strategies (fencing, netting, enclosures); and when any of these methods fail, to take corrective actions, like obtaining kill permits for hunting. Wildlife monitoring and related GAPs should be documented.

If I choose to be audited on the ‘Field Harvest and Field Pack’ section of the USDA GAP audit, does the auditor need to see me harvest each specific crop?

Many growers have a diverse mix of crops being grown throughout the season. Auditors will typically just need to see on crop from each main category of crops that are harvested in a similar manner. For example, if one grows tomatoes, peppers, and eggplants, and all are hand picked into plastic bins, just seeing one of those crops harvested is enough. Another example would be if you are growing tomatoes, sweet corn, jalapenos, potatoes, pumpkins, cabbage, and sweet potatoes, you would then group similarly harvested crops together: tomatoes, jalapenos (hand picked into bins); sweet corn (jerked into large bins); pumpkins, cabbage (cut with tool into bins); potatoes, sweet potatoes (machine dug). In this example, the auditor would just observe you harvesting one crop from each of these groups.

When harvesting, should I have a way to label product moving from the field to the packing area (if re-packed)?

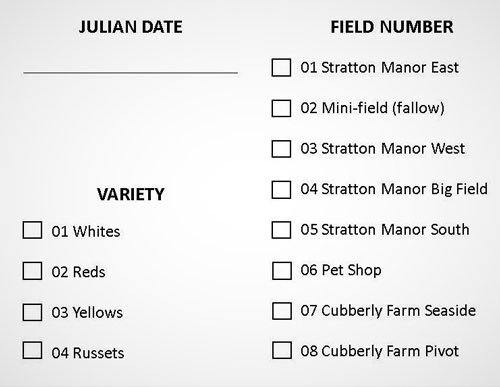

Yes, this is a really good idea! While for small farms this may be less of an issue, when there are multiple fields with the same type of crop or multiple farm locations, it is definitely important to be label to identify the farm and field from which it came. This is important for traceability, should there be any food safety issues. Also, it is a great way to document yields for particular farm areas. There are different ways to identify the farms, fields, and/or crops. One way is to make labels and laminate them, and then have a large set of labels that can easily be placed into harvest bins while harvesting. This makes it super easy when re-packing, especially amidst harvesting and re-packing busyness. For operations with large harvests, another idea is to create picking slips with check boxes that can easily be checked. This is ideal with truckloads of harvest being transported to packing houses for washing and packing, such as with tree fruit or root crops.

Can pathogens be removed by washing produce?

People are surprised when they learn that washing produce with water/detergents or even other sanitizers does not completely remove foodborne pathogens from produce. This question is explored more by Dr. Ben Chapman, a food safety researcher and colleague at NC State, who addressed a closely related question, “What is the most effective means of cleaning fresh produce to remove micro-organisms that could make you sick?” Here was his reply:

“Vigorously rinsing the produce under running water is the most effective way of removing the microbes that cause foodborne illnesses – you don’t need soap or any special& cleaning products, but while washing your produce may remove some pathogens, it doesn’t eliminate risk altogether.”

“At best you get a two log reduction – that’s a 99 percent reduction in microbes. That seems good, but it’s not great. While washing can help reduce pathogen contamination, it shouldn’t be relied on as the only control measure.” By comparison, cooking food results in a six log reduction in viable microbes. That means the population of viable microbes gets cut by 99.9999 percent(!).

The difference between 99 percent and 99.9999 percent is important because some fruits and vegetables can be contaminated with thousands of microbes. And we know that, on average, most microbial food-borne illnesses are caused by foods that are contaminated by only 20-30 organisms. So washing off 99 percent of the microbes doesn’t help much if a food was carrying thousands of microbes to start with.

Another key consideration is that some pathogens can actually infiltrate into the tissues of fruits and vegetables, creating a situation where the water/detergents/sanitizers and/or scrubbing would never reach them anyway. One example is that E. coli (if on the surface of leafy greens) can infiltrate the plant tissue through the stomata on the surface; or that Salmonella(if on the surface of a tomato) can infiltrate a tomato through its stem scar. So, the take-home message here is to understand the risks and prevent contamination from happening in the first place. And, when thinking of washing produce during post-harvest handling, always be aware of the potential for infiltration of contaminated water into those fruits and vegetables that tend to have this issue.

What recommendations can you give for sanitizing tools, bins, and packing areas?

First, it is important to understand the difference between cleaning and sanitizing. Cleaning is the process of removing dirt and residues from a food contact surface, whereas sanitizing is the process of treating a contact surface with a sanitizing solution that will kill most mircroorganisms to a non-harmful level. Thus, before sanitizing tools, bins, and packing areas, it is important first to make sure they are always cleaned properly. There are different kinds of sanitizers, each with pros and cons. Some considerations are efficacy in presence of high organic matter and high water pH, corrosivity, and cost of the product. Additionally, it is very important that the sanitizers are labeled for use with food contact surfaces, since anything coming into direct contact with the fresh produce is a direct contact area. The following resources can assist you in deciding what sanitizer makes the most sense for your particular operation:

https://store.extension.iastate.edu/Product/6546

http://ucfoodsafety.ucdavis.edu/files/26437.pdf

What are some considerations for GAPs for tree fruit production?

Some key questions to consider are:

- What is the source and quality of the irrigation water? Has it been tested?

- What is the quality of the water used for spray applications? Since the water is touching the edible portion of the crop, it must be tested, and treated, if needed.

- Are any manures applied at the base of the trees? If so, then you will need to make sure that the bottom of shoes placed on ladders do not pose a cross-contamination risk during the harvesting stage.

- Make sure picking containers (bags or wooden crates around neck, if used) are kept free of contamination; cloth bags should be washed and sanitized between uses; crates should be carefully cleaned (obviously they cannot be sanitized, but should be stored properly, keeping free of dirt, etc.); if plastic bins are used, they should be cleaned and sanitized.

- If harvested fruit is put into larger bins, the bins should also be cleaned and sanitized (if possible); wooden crates can be swept broom clean, stored upside down, and inspected prior to each harvest event. Wooden bins are still used in many orchards; however, producers usually lose the points on the questions related to whether the bins are new or sanitized.

- Monitoring for wildlife is a must and documentation of any corrective actions taken to remediate problems. When product is being harvested, workers should have a visual inspection and procedure for discarding any product found to be contaminated by animals.

- Worker health and hygiene is important, especially in relation to ladders, watching for hands being contaminated by climbing, clothing issues, boots/shoes, and having proper facilities available.

- Transport to storage areas—make sure product is covered to prevent contamination; product should never be put under trees or power lines while waiting to be transported into storage.

- Having well defined field maps of all locations of product is crucial in order to provide traceability

Can a farm using an aquaponics production system be GAP certified?

Often growers assume that being GAP certified is not possible with an aquaponics operation. While aquaponics operations do pose unique risks, it is possible to be GAP audited IF the operation adequately addresses several concerns. When presented with a request for audit services for an aquaponics operation, the following guidelines are used (as per USDA):

- These types of operations can be approved for being audited on a case by case basis.

- The farm or operation should submit a summary of the fish growing and plant growing operation. A flow chart showing the places and processes that the water passes through is a very helpful summary. This is part of the HGAP audit water irrigation risk assessment.

- We will not certify aquaponics operations where the fish are living under the plants in the same tanks; they must be separated.

- We have certified aquaponics operations where the fish are kept in tanks separate from the plant, the water is filtered and sanitized before it is used in the plant beds, and the fish tanks are physically separated from the plants so there can be no cross contamination by spilled or leaking water.

- The water sanitation may include ultraviolet light as one method. There may be other good sanitation methods such as ozonation or chlorination. There should be routine water tests (at least monthly) conducted to verify effectiveness of the treatment performed.

- Some good SOP’s we have found are: Persons who are handling the fish or fish equipment cannot handle the plants or plant water and equipment without first sanitizing their hands. Aprons worn in the fish area and plant area are kept separate.

- There must be provisions to prevent edible portions of plants from coming in contact with the tank water.

- The audit standard that we suggest for aquaponics operations is the Produce GAPs Harmonized Food Safety Standard. More information can be found in the Producer Resources section under GAP Certification. For more information on aquaponics food safety, explore the following resources:

What if my buyer requires GAP certification before they will purchase my product? How can I still perform a mock recall?

A mock recall is simply selling some of your product to a buyer and having all the paperwork to show that you have a traceability system in place and the ability to trace your product from the field to the buyer, as well as the buyer being able to trace your product back to your farm. As a “first timer”, you have to be able to prove to the auditor that the recall/ traceability plan is intact and that it works. A mock recall is proof of what the documents will look like, what info it will consist of and what you’re going to do about it, and how you’re going to go about it. Regardless of the audit scheme, the auditor expects that a mock recall has been performed prior to the actual audit. Remember that a mock recall can be done with someone who does not even “require” GAP certification—even if it was just one box of product! You could sell a small amount if something to a buyer and then do your mock recall; you just have to have the plan in place and be able to prove it works. The key points to make sure you have are:

- Clearly defined traceability system with field and crop codes, along with date harvested, as well as a means for keeping track of your transactions to various buyers. There is no one right way of doing the system—the key is to be able to track your product should there ever be a suspicion of an outbreak.

- Paperwork of the transaction (like invoice) which must include the product traceback code quantity sold, date of transaction, and name of your farm, along with who you sold to.

- Paperwork documenting that you have notified the buyer that you are performing a mock recall on the product. This needs to include the same information as mentioned above. This cannot just be a phone call; you should have a paper trail of sorts—either a FAX, email or letter, which is signed.

- Additionally you must have a paper trail for the response from the buyer, including the same information and receipt of the product by them. Again, the response cannot just be a phone call, but should be in writing and signed (electronic signature is ok).

When should I begin preparing for my GAP audit?

The preparation process is extensive and needs adequate time to complete in a timely manner. Unless a buyer is adamant about an audit needing completion as soon as possible, we strongly encourage growers to be proactive and begin preparing in the late fall. This allows plenty of time to complete all the processes needed and then to schedule the audit for the next year. Remember that the audit has to be performed during the growing season when crop(s) are actively growing. In other words, you cannot be audited for a crop that is not actually growing at the time of the audit. Depending on the particular sections of the audit you decide to be audited for, you may be required to demonstrate your harvesting and handling practices of the crop(s) in question, which means those crops must be at the harvest stage for the auditor to view.